Super Spartan Build by Roberta Part 3

Posted by Gayle Brantuk on Dec 9th 2011

To read the previous posts in this series, click the links below: Part 1 Part 2

Wednesday, November 23, 2011

I completed fitting up the frames into the chine/bottom assembly and have been sanding and gluing them in this week. I leveled out the bottom and did frame 1 and 3 yesterday. Today I did frame 2 and some fitting on the transom. Other than the notch for frame 2, there is nothing notable about the others except to get them located properly and squared up.

The frame kit was nice to have as all the putzy work of putting them together was done by Glen L. The frames are quality Philipine mahogany and DF plywood. If I were to make another Super Spartan, I would opt to use okoume or maranti instead of the DF, but that is only my preference to the nicer grain and color. The DF is, otherwise, fine. I may use some leftover 4 mm maranti to dress up the DF that is more exposed, like the ends of the sponsons. I will be using some 6 mm okoume to dress up the transom, though. I wish Glen L would start making frame kits again (hint hint) as they are nice and sure speed things up.

Wednesday, November 2, 2011 Note

Anyone familiar with the Super Spartan build might notice my two screwups.

The obvious one is frame 1 is backward. I was intent on getting the frame member lined up on the registration line. I noticed after the glue cured that I put it on backward. It's not a big deal and will not really change anything. It just offsets the blocking for the deck 1/2".

But that's OK because I also screwed up on the length of the aft side planks. There is a note on the pattern to make the planks 3/4" longer to allow for the plank to overlap the transom ply. I had my pattern sheet copied and the note on the copy was illegible and I missed it and made the plank per the pattern without the extra 3/4".

So I got out my Zona saw and wacked off 1/2" off the battens and chines. I don't think the boat will notice either mistake, but I wanted to mention it should anyone using my blog as a guide be confused over them. In retrospect, I remember reading the note on the original, but I just plain old forgot. My bad!!!!

Sunday, November 27, 2011

Minor errors can be repaired or, if they do not alter or weaken the structure and can be worked around, ignored. Best to not make too many as that leads to sloppy workmanship.

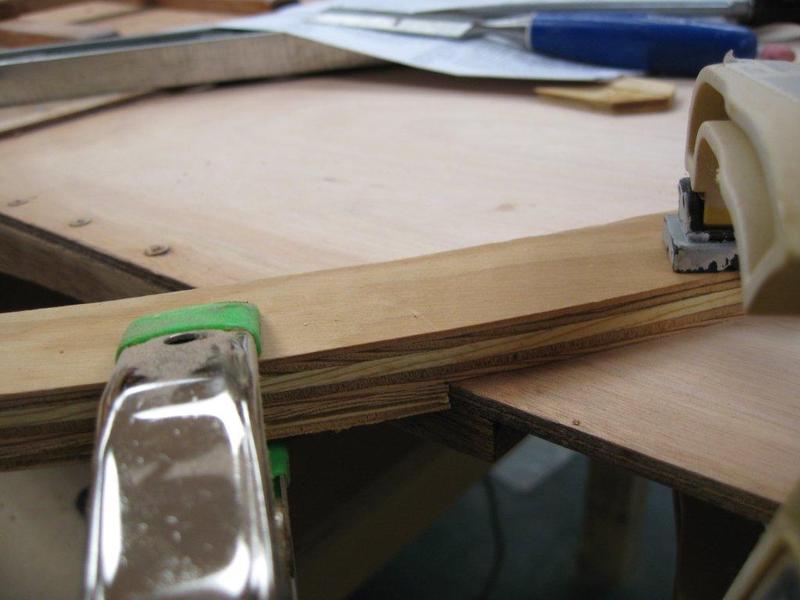

This weekend I installed the bow pieces. Two pieces are laminated from 1/4" and 1/2" plywood and run from frame 2, through frame 3 and butt up against the bottom ply at the front end of the runner chine. The pattern allows for a bit longer so it can be sheared off to fit the bottom plank. The other two bow pieces are cut from 1/2" plywood and are laminated to the first two pieces and glued to the bottom plank where they meet in the center.

When laying the bow pieces up it will be helpful to level the structure and prop up the bow so it has it's natural pitch upward as defined by the curve in the runner chines. Yesterday I layed in the pieces that run between the frames to the front sides of the bottom plank. Today I trimmed those pieces to butt up to the bottom plank. Next the front bow pieces were fitted and trimmed, then glued and clamped.

Great work Roberta! Thank you for your excellent posts and even for sharing mistakes with us. That's the best way to learn, is by the mistakes of others because we'll each have our share as well. May as well eliminate a couple here and there!

In response to Roberta's subtle hint about frame kits, I don't like to say we'd never build them again, so I won't. But, we discontinued them for a reason and the main one was that we didn't sell enough to make it a viable part of our business. Most prefer to use our full size patterns and build their own...

Watch for Part 3 next week!