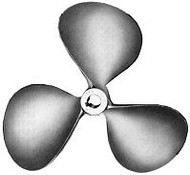

Inboard Propeller Installation Procedures

Posted by Gayle Brantuk on Feb 27th 2019

Glen-L carries a selection of Johnson OJ Propellers from their "Legend" line. Johnson has been making props since 1936, so they know what they're doing! See our full line of props on our site.

Following are instructions courtesy of Michigan Wheel, for installing a propeller:

- Push propeller snugly onto shaft taper WITHOUT key in either keyway (propeller or shaft).

- Make sure the propeller is snug and there is no side to side movement by gently moving propeller back and forth.

- Make a line on the shaft with a non-graphite marker at the forward end of the propeller where it stops up against the shaft taper.

- Remover propeller.

- Put key into keyway on shaft taper with radiused or chamfered corners down in shaft keyway (if propeller shaft keyway has radiused corners).

- Put propeller onto shaft taper.

- Check to see that the propeller moves back to the forward line made in Step 3. If it does, skip down to Step 8. If not, perform the following:

- Remove propeller from shaft.

- Place a file on a flat surface area or work bench.

- Run opposite end of chamfered key back and forth over file (to remove any burrs) with a downward pressure on key until side being filed is clean.

- Install cleaned key in shaft keyway with chamfered corner side down in shaft (the cleaned, filed side up in keyway).

- Replace the propeller on the shaft and fit snugly on taper. Check to see if it reaches the line made as in Step 7. If it does not line up then repeat Steps "a" through "e".

NOTE: A vise can be used to hold key while it is being filed, but care must be taken not to overly tighten the vise which can cause burrs and irregularities on the key.

- Remove propeller from shaft.

- When propeller hub moves to correct position, install propeller nut on shaft and torque to seat the propeller. Install the torque jam nut also, if your shaft is so equipped.

- Install cotter pin at end of the shaft.